E Ink is the inventor of several novel types of electrophoretic ink, often called electronic ink. When laminated to a plastic film, and then adhered to electronics, it creates an Electronic Paper Display (EPD). Although futuristic-sounding, electronic ink is actually a straightforward fusion of chemistry, physics and electronics. It's so much like paper, it utilizes the same pigments used in the printing industry today.

Key features:

The two pigment electronic ink system is made up of millions of tiny microcapsules, each about the diameter of a human hair. Each microcapsule contains positively charged white particles and negatively charged black particles suspended in a clear fluid. When a positive or negative electric field is applied, corresponding particles move to the top of the microcapsule where they become visible to the viewer. This makes the surface appear white or black at that spot.

For the E Ink Prism film, we utilize different colored pigments from the standard black and white. You can learn more about Prism.

E Ink also offers a 3-pigment ink system in a microcup structure. This ink was engineered specifically for Electronic Shelf Labels (ESL). It works similarly to the dual pigment system, in that a charge is applied to the pigments, and to a top and bottom electrode to facilitate movement. However, instead of the use of microcapsules, this system utilizes Microcups®, which are filled with the liquid and sealed.

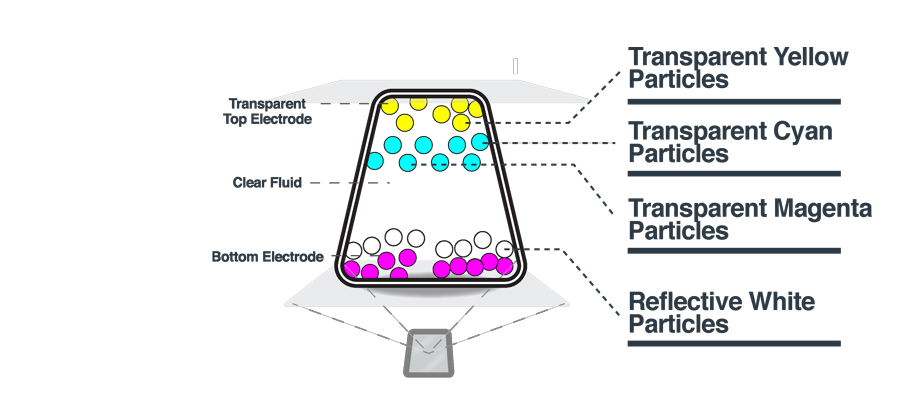

In 2016 E Ink showcased a multi-pigment ink system, Advanced Color ePaper (ACeP). ACeP achieves a full color gamut, including all eight primary colors, using only colored pigments. The ink can be incorporated into either microcapsule or microcup structures. Color is achieved by having all the colored pigments in every pixel, removing the need for a color filter array. ACeP maintains the ultra-low-power and paper-like readability under all lighting conditions of regular E Ink ePaper.

Learn how these different ink systems are utilized in our films.